-

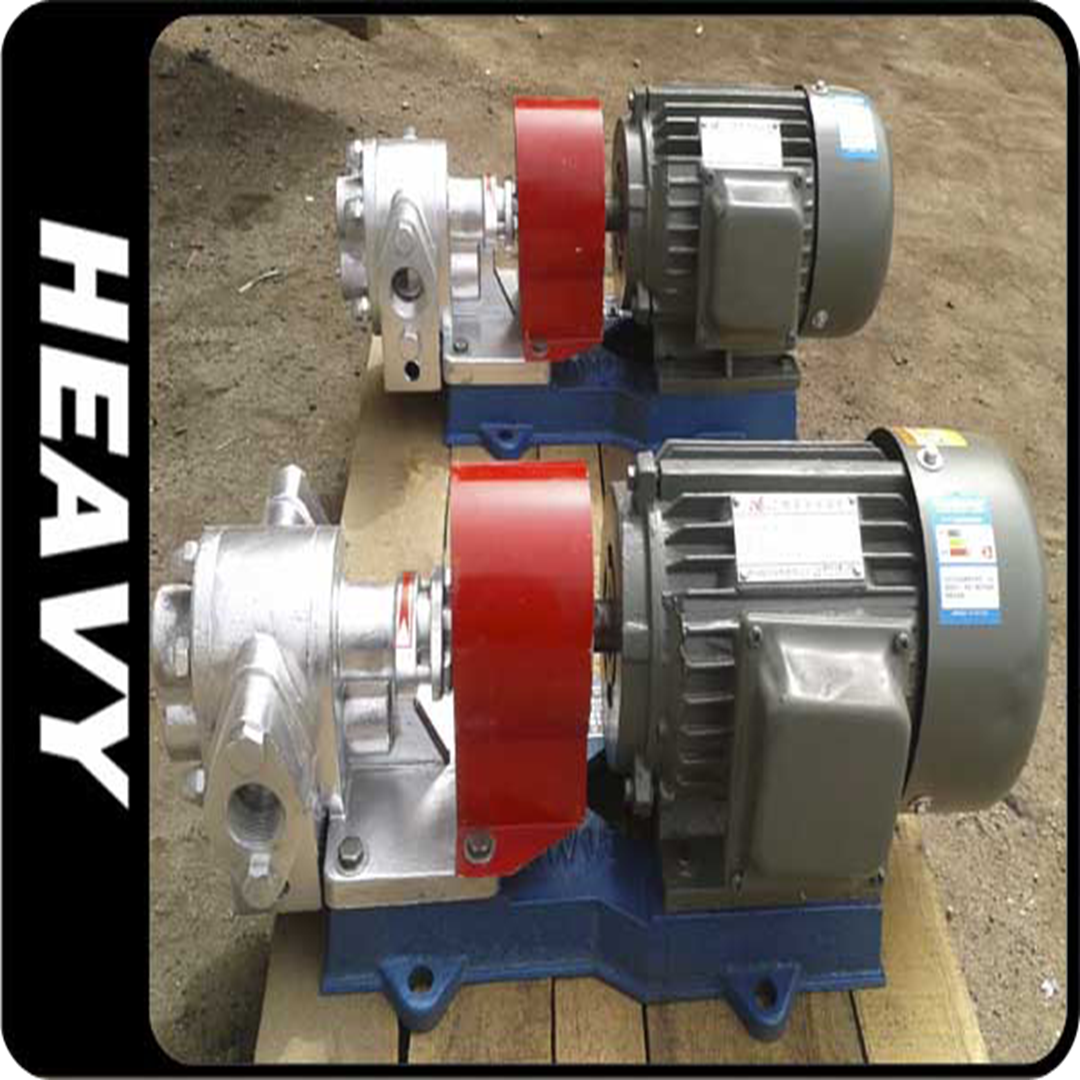

Product production process

Application:

It applies to delivering non-corrosive lubricating-oil orequivalent liquid without solid particles and fibres attemperature below 300°C and with the viscosity of 5x 106~1.5x10“m2/s (5-1500cSt)Reducing the speed, the pump can delivery the liquid that theviscosity can be up to 5x 10'cSt.

-

Product Features

Application Scope

It can give performance as transfer pump or booster pump inoil delivery system. It can be also applied as fuel pump fordelivery system, pressurization and injection in fuel supplysystem and in all industry fields as lubricating pump.

-

Product application

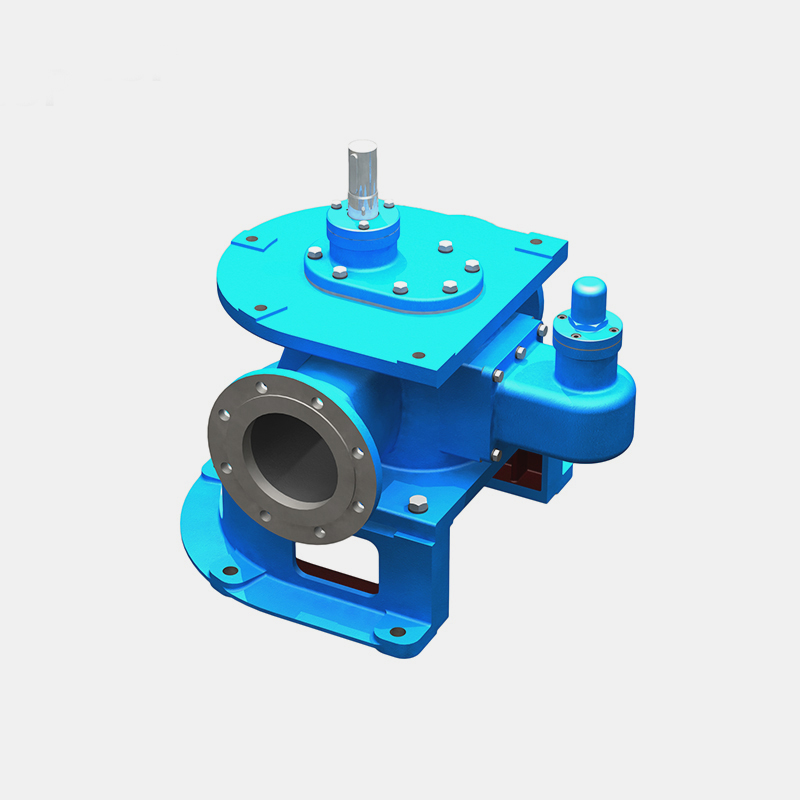

Structure Features

KCB series gear pumps are mainly composed of gears,axles, pumpbody,pump cover, safety valve and axle-end seals etc. (Speicalrequirement, magnetic force drive and zero-leakage structure canbe selected.)The heattreated gears have the advantage of higherhardness and intensity,and rotate with the axles inside thereplaceable bearing sleeves.All of pump's parts can belubricated by delivered medium when working.

The pump is properly designed with leakage and returnchute,which lets the gears bear the least torque force andreduces load and wear on bearings in order to raise pump'sfficiency.

It is also designed with safty valve for protection againstoverload. The full return flow pressure of the safety valve is1.5 times higher than the rated exhaust pressure of the pump. Itcan be also adjusted within the allowance of exhaust pressurerange according to circumstances. But please note the safty valvecan't be applied as pressurereducing valve for long time. You may install pres surer educing valve separately on pipe-line if needed.The direction of rotation is clockwise viewed from coupling end.

-

Product performance

-

AddressNo.39, Tanan Road, Shijiazhuang, Hebei, China(050024)

AddressNo.39, Tanan Road, Shijiazhuang, Hebei, China(050024) Hotline

Hotline Wechat

Wechat