Home ◇ PRODUCTS ◇ Slurry pump ◇ HS Series

-

Product production process

The Cr26 Chromium Iron Alloy HS Series Slurry Pump, engineered for high-wear and high-corrosion environments, is a high-efficiency wear-resistant pump. Manufactured with advanced Cr26 chromium iron alloy through precision casting, its flow components exhibit exceptional wear and corrosion resistance, significantly extending equipment lifespan. Compared to traditional material pumps, this design increases service life by several to dozens of times while optimizing hydrodynamic performance to enhance conveying efficiency and operational stability. Widely applicable in heavy industries including metallurgy, mining, power, chemical, petroleum, and paper manufacturing, it ensures long-term stable operation under complex conditions.

Key attributes

application

Water Treatment Solutions

pressure

Other

customized support

OEM

warranty

2 Years

place of origin

OEM

power source

Electric

structure

Single-stage Pump

model number

HS

brand name

HEAVY

Pressure

High Pressure

Theory

Centrifugal Pump

StandardorNonstandard

Standard

Design

Traditional submersible sand pump

Material

Cr26

Factory experience

15 years direct factory

Centificate

ISO9001 CE

Warranty

1year

Usage

submersible sand pump

Lead time/On-time delivery

Know your supplier

Heavy-Duty Slurry Pump Design: Engineered specifically

for high-abrasion applications like coal washing plants,

this ZJ pump ensures reliable, uninterrupted transfer of

thick slurry with minimal wear.Exceptional Wear-Resistant Performance: Constructed

with premium high-chrome alloy or rubber liners, key

components withstand severe abrasion and corrosion,

dramatically extending service life and reducing replacement

part costs.Optimized for Harsh Industrial Slurry: Ideal

for mining, mineral processing, and coal plant operations,

it efficiently conveys dense, solid-laden fluids with

high efficiency, maximizing productivity in demanding environments.Durable & Cost-Effective Operation: Robust construction minimizes

downtime for maintenance, while the pump's specialized

design delivers superior wear resistance, ensuring a lower

total cost of ownership and long-term investment value.

-

Product Features

Quality Control and After-sales Service System This section will elaborate on the quality control measures for the production process of the Cr26 ferrochromium alloy cast HS series slurry pump, including raw material procurement standards, production process control, key component testing methods, finished product inspection and performance testing, as well as quality management system certification. It also covers the construction of the after-sales service system, including customer service network construction, technical support team configuration, product warranty policy, installation and commissioning services, spare parts supply mechanism, and customer feedback processing mechanism, to ensure the reliability and stability of the product during use, enhance customer satisfaction, and improve market competitiveness

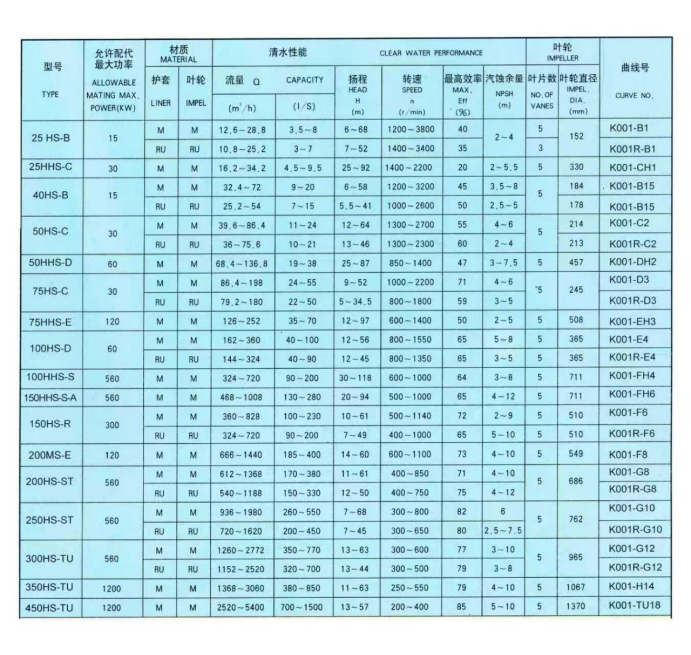

HS Selection Chart and Performance

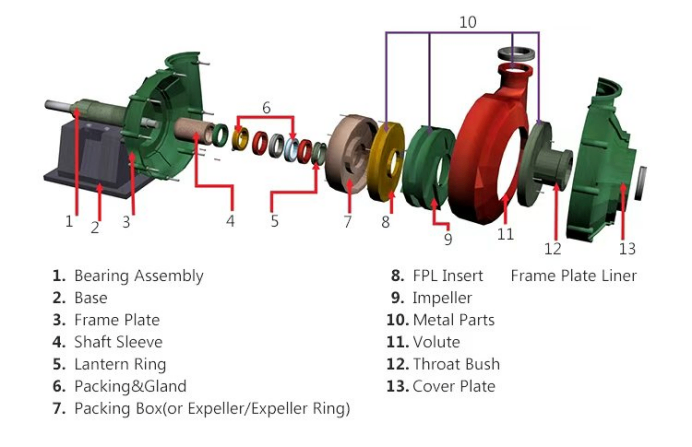

HS on composition

-

Product application

Analysis of Industry Application Fields: The HS series slurry pump, due to its excellent abrasion and corrosion resistance, has been widely used in various industries such as metallurgy, mining, power, chemical, petroleum, and paper-making. It performs exceptionally well under high wear and corrosion conditions, effectively extending equipment service life, reducing maintenance costs, and enhancing overall operational efficiency. In the mining industry, it is used for slurry conveying; in the power industry, for desulfurization systems; in the chemical industry, for acid and alkali liquid conveying; and in the petroleum industry, for oil sand processing. In the paper-making industry, it is used for pulp conveying, among other broad application scenarios. It provides customers with efficient and reliable professional solutions

-

Product performance

The slurry pump has the following characteristics: it is capable of conveying high-concentration fluids. Specifically designed for conveying mixtures of solid particles and chemical substances at high concentrations, the slurry pump can handle the conveyance of high-concentration fluids resulting from the mixing of liquids and solids. This makes it widely used in industries such as coal, chemical, metallurgical, and construction.

Efficient hydraulic performance: The slurry pump boasts excellent hydraulic performance, characterized by high efficiency and low wear rate. It can effectively transport slurry media with high concentration and hard particle content.

Superior anti-clogging performance: The flow passage of the slurry pump is relatively wide, which can effectively resist clogging issues and maintain stable conveying capacity. In addition, the slurry pump also exhibits excellent cavitation resistance

Bearing cooling and lubrication system: The slurry pump is equipped with a properly designed lubrication and cooling system to ensure the bearings operate normally at low temperatures and extend the service life of the pump.

Wear-resistant material: The flow-through components of the slurry pump are made of special wear-resistant materials, which exhibit excellent wear and corrosion resistance. After undergoing special treatment, their range of application is further expanded.

Diverse pump head structures: The pump body and cover of the slurry pump are equipped with replaceable wear-resistant metal liners. The flow-passing components such as the sheath, impeller, and guard plate are made of high-chromium wear-resistant metal. Different types of slurry pumps also offer flexibility, such as adjusting the outlet position and rotating for installation and use.

Diverse material options: To cater to the needs of various conveying media and ensure a long service life, slurry pumps are constructed with corrosion-resistant materials such as stainless steel, titanium, and acrylic-coated plastics.

Mechatronic design: The slurry pump adopts a direct coaxial connection between the pump and the motor, achieving mechatronic integration, which makes the pump structure compact and easy to operate.

In summary, slurry pumps are widely used in the power, metallurgical, coal, and other industries due to their high hydraulic performance, good anti-blocking performance, reliable sealing performance, wear-resistant materials, and diverse pump head structures.

HS Curve

-

AddressNo.39, Tanan Road, Shijiazhuang, Hebei, China(050024)

AddressNo.39, Tanan Road, Shijiazhuang, Hebei, China(050024) Hotline

Hotline Wechat

Wechat